Digital calipers and ultrasonic thickness gauges are essential tools for precision measurements in various industries, especially automotive repairs. Digital calipers offer unparalleled accuracy down to fractions, data storage, and displays, making them versatile for material thickness tasks. Ultrasonic thickness gauges use high-frequency sound waves for non-destructive testing, ensuring material integrity without damage, and are ideal for auto detailing and restoring vehicle finishes. When choosing between the two, consider their strengths: digital calipers for precise, millimeter measurements in intricate tasks, and ultrasonic thickness gauges for quick, reliable thickness measurements across various materials during vehicle restoration.

In the realm of repairs, precise measurements are paramount. Traditional methods meet modern alternatives in the form of digital calipers and ultrasonic thickness gauges. This article delves into these tools’ unique capabilities, focusing on their application in repair solutions. Digital calipers offer accurate, direct measurements, while ultrasonic thickness gauges provide non-invasive depth sensing. Comparing their features allows professionals to choose the optimal tool for the job, ensuring efficient, effective repairs with enhanced precision, especially when dealing with delicate materials and intricate designs.

- Understanding Digital Calipers: Precision Measurement Tools

- The Rise of Ultrasonic Thickness Gauges: A Modern Alternative

- Comparing Features and Applications for Optimal Repair Solutions

Understanding Digital Calipers: Precision Measurement Tools

Digital calipers are precision measurement tools that have become indispensable in various industries, including automotive repairs. These devices offer accurate and repeatable measurements, making them a top choice for professionals seeking meticulous results. When it comes to assessing the thickness of materials, such as in vehicle repair or auto painting, digital calipers provide consistent readings down to the smallest fraction, ensuring every detail is accounted for.

Unlike traditional measuring tapes, digital calipers offer enhanced functionality with features like data storage and advanced displays, allowing users to capture and analyse measurements efficiently. This level of precision is particularly valuable during car repair services, where even minor variations in thickness can impact the final outcome. With their versatility and accuracy, digital calipers stand as a reliable alternative to ultrasonic thickness gauges for those seeking precise measurements without advanced sonar technology.

The Rise of Ultrasonic Thickness Gauges: A Modern Alternative

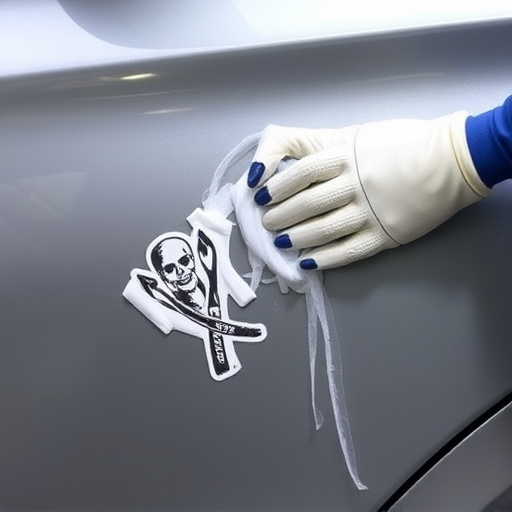

In recent years, the automotive industry has witnessed a significant shift towards advanced measurement tools, marking a clear rise in the adoption of ultrasonic thickness gauges. These modern alternatives to traditional digital calipers are transforming various sectors, including tire services, auto dent repair, and car body restoration. The ultrasonic thickness gauge offers unparalleled precision in gauging material thickness, making it an indispensable asset for professionals seeking accurate and efficient solutions.

By employing high-frequency sound waves, these innovative gauges provide non-destructive testing capabilities, ensuring the integrity of materials without causing any damage. This feature is particularly valuable in delicate repair processes, allowing technicians to make informed decisions with confidence. As technology continues to evolve, ultrasonic thickness gauges are poised to become even more versatile, further solidifying their place as a game-changer across multiple sectors that rely on precise measurements for top-notch repairs and restaurations.

Comparing Features and Applications for Optimal Repair Solutions

When comparing digital calipers and ultrasonic thickness gauges for repairs, understanding their unique features and applications is key to selecting the optimal tool for the job. Digital calipers offer precise measurements in millimeters or microns, making them ideal for detailed tasks like metal fabricating, precision engineering, and even fine jewelry making. Their portability and ease of use make them a versatile choice for various workshops and field settings, including car collision repair and vehicle restoration projects.

In contrast, ultrasonic thickness gauges utilize high-frequency sound waves to determine material thickness non-destructively. This makes them perfect for auto detailing and ensuring minimal interference with the final finish. Ultrasonic thickness gauges are highly accurate and can measure a wide range of materials, from plastics to composites, making them indispensable in modern vehicle restoration efforts. For applications requiring quick, reliable thickness measurements without damaging the surface, these gauges stand out as a game-changer in the repair industry.

Digital calipers and ultrasonic thickness gauges offer distinct advantages in repair work, each with its own strengths. Digital calipers excel in precise, direct measurements, making them ideal for a range of applications. Ultrasonic thickness gauges, on the other hand, provide non-destructive testing, allowing for quick assessments without damaging the material. When choosing between the two, consider the specific needs of the repair project: digital calipers for detailed, physical measurements and ultrasonic thickness gauges for efficient, non-invasive thickness verification. Combining these tools can lead to optimal results in various repair solutions.