An ultrasonic thickness gauge is a non-destructive tool that measures material thickness using high-frequency sound waves. Essential in vehicle repair and painting for structural integrity and quality refinishing, it provides precise results needing deep material understanding and control over environmental factors like temperature and humidity to avoid common mistakes and ensure accurate measurements.

Learn how to interpret readings from an ultrasonic thickness gauge with confidence. This guide breaks down the fundamentals of these non-destructive testing tools, empowering you to accurately measure material thickness. We’ll explore key factors influencing measurements, common mistakes to avoid, and practical tips for consistent results. Maximize your understanding of ultrasonic thickness gauging and unlock the power of this valuable measurement technique.

- Understanding Ultrasonic Thickness Gauge Basics

- Interpreting Measurements: Key Factors to Consider

- Common Mistakes and How to Avoid Them

Understanding Ultrasonic Thickness Gauge Basics

An ultrasonic thickness gauge is a versatile tool used to measure the thickness of materials non-destructively. It works by transmitting high-frequency sound waves through the material and measuring the time it takes for the waves to echo back. This technology is especially useful in industries such as vehicle collision repair, auto body repair, and car paint services where accurate thickness measurements are crucial for ensuring structural integrity and proper refinishing.

Understanding how an ultrasonic thickness gauge operates involves grasping key concepts like sound wave propagation, echo time measurement, and conversion of time to thickness. These gauges offer precise and consistent results, making them indispensable tools for professionals in various fields who require detailed material analysis without causing damage to the surface being examined.

Interpreting Measurements: Key Factors to Consider

When interpreting measurements from an ultrasonic thickness gauge, several key factors come into play to ensure accurate and reliable results. First and foremost, it’s crucial to understand the material being measured. Different materials have distinct acoustic properties, which can affect how sound waves interact with them. For instance, metal and plastic will yield different readings due to their varying densities and reflectivity. Therefore, identifying the material is a foundational step in correct interpretation.

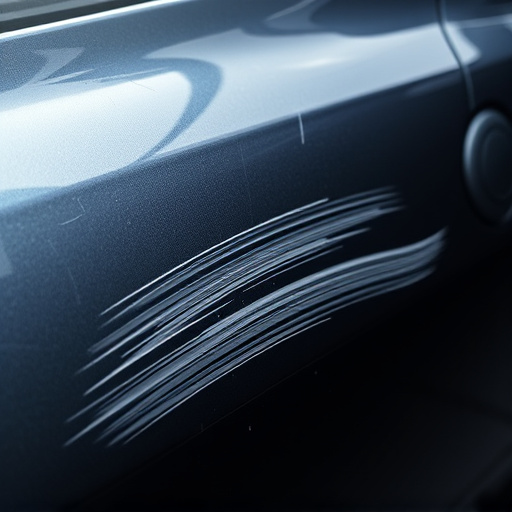

Additionally, environmental conditions can significantly impact measurements. Factors such as temperature and humidity can cause variations in the speed of sound transmission, leading to potential errors. Auto painting or auto collision centers often deal with fender benders and other minor damages, where quick and precise thickness gauge readings are essential for accurate repairs. To mitigate these influences, it’s important to calibrate the gauge according to the material being measured and maintain a controlled environment during the measurement process.

Common Mistakes and How to Avoid Them

When using an ultrasonic thickness gauge, there are several common mistakes that users often make. One of the most frequent is assuming that the readings are always accurate without proper calibration. It’s crucial to regularly calibrate your ultrasonic thickness gauge to ensure precise measurements, especially in industries like automotive body shops and auto collision centers where accuracy matters for repairs like car dent removal.

Another mistake is not considering environmental factors. Temperatures and humidity can significantly impact the accuracy of readings. Always take these into account and follow best practices: keep the gauge at a consistent temperature, away from direct heat sources or cold drafts, and in an area with optimal humidity levels. By avoiding these common pitfalls, you’ll be able to rely on your ultrasonic thickness gauge for dependable results in tasks such as car dent removal and other precision measurements in auto collision centers.

An ultrasonic thickness gauge is a powerful tool for accurately measuring material thickness, but proper interpretation of readings requires an understanding of key factors and avoiding common mistakes. By grasping the fundamentals outlined in this guide—from basic gauge operation to potential errors—you’ll be well-equipped to rely on your ultrasonic thickness gauge as a reliable and consistent measurement device.