An ultrasonic thickness gauge uses high-frequency sound waves to measure material thickness non-destructively. It requires pre-use inspections, regular calibration, and proper handling for accurate readings in industries like automotive repair. Key maintenance practices include protective gear, storage away from direct sunlight, transducer cleaning, and periodic calibration.

Unleash the full potential of your ultrasonic thickness gauge with our comprehensive guide. Discover best practices for achieving precise, reliable measurements in various applications. From understanding the cutting-edge technology behind these tools to mastering pre-use checks, calibration techniques, and safe handling protocols, this article is your go-to resource for optimal performance. Learn how to maintain accuracy, extend device lifespan, and elevate your material thickness analysis to new heights with expert tips tailored for professionals.

- Understanding Ultrasonic Thickness Gauge Functionality

- Pre-Use Checks and Calibration Procedures

- Safe Handling and Maintenance for Accurate Readings

Understanding Ultrasonic Thickness Gauge Functionality

An ultrasonic thickness gauge is a non-destructive testing tool that employs high-frequency sound waves to measure material thickness with precision. It works by transmitting an ultrasonic signal through the material and calculating its time of flight to determine thickness. This technology is highly versatile, finding applications in various industries such as automotive repair services, manufacturing, and even dent repair at collision repair centers.

Understanding how this gauge operates involves grasping the principles of ultrasound. The tool emits sound waves that travel until they encounter an interface between materials with differing properties, like air and metal. At this point, the wave reflects back to the gauge, which measures the time it takes for this round trip. This data is then converted into a thickness measurement, offering an accurate and reliable way to assess material depth without causing damage, unlike traditional cutting or drilling methods.

Pre-Use Checks and Calibration Procedures

Before using any ultrasonic thickness gauge tool, a thorough pre-use inspection is imperative. This involves checking the device for any visible signs of damage, ensuring all components are intact and properly connected, and verifying that the power is on and the display is functional. Additionally, confirm that the gauge is set to the appropriate unit of measurement (e.g., millimeters or inches) based on your specific application needs, such as in car body repair where precision is paramount.

Calibration is another critical step in maintaining accurate readings with an ultrasonic thickness gauge. Regular calibration ensures the device provides reliable and consistent measurements. Many modern gauges come with built-in calibration routines that guide users through the process. For those used in Mercedes Benz collision repair or other vehicle collision repair scenarios, following the manufacturer’s recommended calibration schedule is essential to guarantee optimal performance and ensure the integrity of repairs.

Safe Handling and Maintenance for Accurate Readings

Proper handling and regular maintenance are paramount to ensuring accurate readings from an ultrasonic thickness gauge. Always wear protective gear, including gloves and safety glasses, when operating the device. This is crucial to prevent any potential damage to the sensor or user injury. Avoid contact with hazardous materials, as they can interfere with the instrument’s precision.

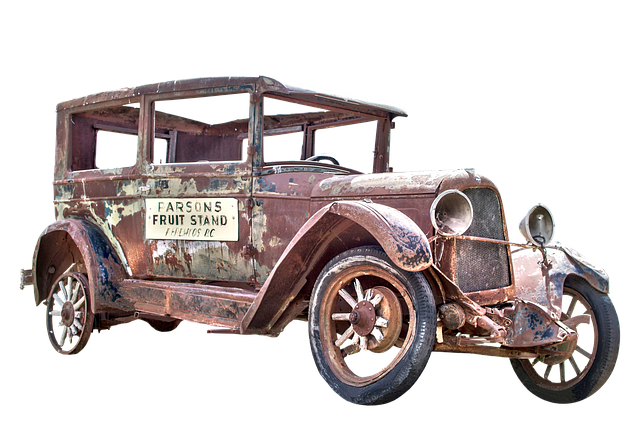

When not in use, store the gauge in a clean, dry place, away from direct sunlight. Regular cleaning of the transducers and calibration checks are essential maintenance practices. For auto repair shops, collision centers, or classic car restoration enthusiasts, keeping these steps in mind will help maintain the integrity of measurements, ensuring safe and reliable results for every project.

In conclusion, mastering the art of using an ultrasonic thickness gauge requires a combination of understanding its functionality, adhering to strict calibration and pre-use checks, and implementing safe handling practices. By consistently following these best practices, users can ensure precise and reliable measurements, making the ultrasonic thickness gauge an indispensable tool for various industries.