Ultrasonic thickness gauges are indispensable tools for material analysis across diverse sectors, ensuring precise accuracy through high-frequency sound wave measurements. While surface contaminants and material inhomogeneity can cause misreadings, proper calibration, Standard Operating Procedures (SOPs), and technician training mitigate these errors. Widely used in automotive body work, dent removal, and painting, these gauges are critical for maintaining structural integrity, safety, and customer satisfaction in industries where consistent material thickness is essential.

Ultrasonic thickness gauges are essential tools in various industries, offering precise measurements of material thickness. This technology employs high-frequency sound waves to determine depth, making it invaluable for quality control and precision crafting. However, misreadings can occur due to factors like surface conditions, material properties, or measurement setup. This article explores these challenges, delving into the common causes of errors and empowering technicians with proven strategies to prevent them, ensuring accurate and reliable ultrasonic thickness gauge readings.

- Understanding Ultrasonic Thickness Gauges: How They Work and Their Applications

- Common Causes of Misreadings and Their Impact

- Techniques and Best Practices for Technicians to Prevent Misreadings

Understanding Ultrasonic Thickness Gauges: How They Work and Their Applications

Ultrasonic thickness gauges are innovative tools that have revolutionized various industries, especially in the realm of material analysis and quality control. These devices utilise high-frequency sound waves to measure the thickness of materials non-destructively, making them invaluable for ensuring precision in numerous applications. The technology behind these gauges involves sending ultrasonic pulses through a material and calculating the time it takes for the echo to return. This simple yet powerful principle allows technicians to determine the thickness of various substances with remarkable accuracy.

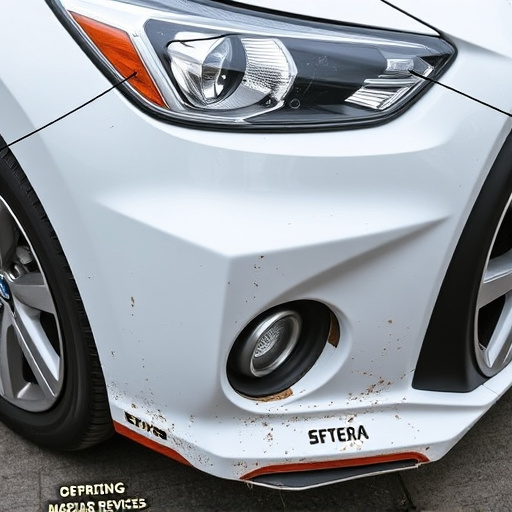

In industries such as automotive body work, dent removal, and auto painting, ultrasonic thickness gauges play a pivotal role. They help ensure the integrity of materials used in vehicle construction, enabling precise measurements during repairs or replacements. By accurately assessing panel thickness, technicians can avoid misreadings that might lead to subpar repairs, ensuring the structural soundness of vehicles. This technology’s versatility extends beyond the automotive sector, finding applications in manufacturing, construction, and even packaging industries where accurate material thickness is critical for product quality and consistency.

Common Causes of Misreadings and Their Impact

Misreadings with ultrasonic thickness gauges can arise from several factors that impact the accuracy of measurements. Common causes include surface contaminants like grease, dust, or paint overcoats, which can disrupt the transmission and reception of ultrasonic waves. Another significant contributor is material inhomogeneity, where the structure or composition of the material varies across its thickness, leading to skewed readings. In the context of vehicle bodywork, such as during car body repair or collision damage repair, these misreadings can result in substantial issues. Inaccurate measurements may lead to incorrect assessments of damage extent, inappropriate selection of replacement parts, and even structural weaknesses that compromise safety and vehicle performance.

Techniques and Best Practices for Technicians to Prevent Misreadings

Technicians play a vital role in ensuring accurate measurements using ultrasonic thickness gauges, which are essential tools in industries like auto collision centers and car paint repairs. To prevent misreadings, they employ several techniques and best practices. First, technicians should always calibrate the gauge regularly to maintain accuracy. Proper calibration ensures that the readings align with the actual material thickness, minimizing errors caused by faulty equipment.

Additionally, creating standard operating procedures (SOPs) for using ultrasonic thickness gauges is crucial. These SOPs should detail each step of the measurement process, including how to position the transducer, apply coupling agent, and interpret results. Following these guidelines consistently helps reduce human error. Technicians should also be trained to account for environmental factors, such as temperature and humidity, which can influence measurements. In the context of dent removal or auto body repairs, where precision is key, adopting these practices enhances work quality and ensures customer satisfaction in car paint repair services.

Ultrasonic thickness gauges are invaluable tools in various industries, ensuring accurate measurements and preventing misreadings. By understanding their functionality and implementing best practices, technicians can significantly enhance precision. Addressing common causes of errors, such as surface conditions and operator variability, is essential. Through proper training, maintaining calibration, and adhering to standardized procedures, technicians ensure the reliability of data obtained from ultrasonic thickness gauges, ultimately fostering improved quality control and informed decision-making processes.