Ultrasonic thickness gauges, utilizing high-frequency sound waves, offer fast and accurate non-invasive depth measurements for vehicle repairs, revolutionizing body panel integrity assessment, scratch and collision repair, and paint thickness management. Optimal performance requires calibration, maintenance, proper sample preparation, staff training, and adherence to manufacturer guidelines, significantly enhancing efficiency and reducing costs in automotive restoration industries.

“In today’s precision-driven manufacturing landscape, accurate material assessment is paramount. This article explores the role of ultrasonic thickness gauges as a game-changer in ensuring quality control. We delve into understanding this advanced technology, offering insights on setting realistic timeline expectations for assessments. Furthermore, it highlights best practices to optimize results and workflows, making your material inspection process efficient and reliable. Embrace the power of ultrasonic thickness gauge technology for enhanced precision.”

- Understanding Ultrasonic Thickness Gauge Technology

- Setting Realistic Timeline Expectations for Assessments

- Best Practices for Accurate Results and Efficient Workflows

Understanding Ultrasonic Thickness Gauge Technology

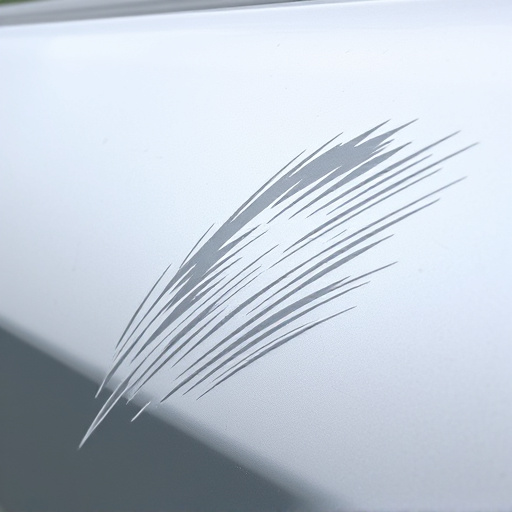

Ultrasonic thickness gauges are innovative tools that have revolutionized various industries, particularly in the realm of vehicle repair. This technology employs high-frequency sound waves to measure the depth or thickness of materials non-invasively. By transmitting ultrasonic pulses through a material and calculating the time it takes for the echo to return, these gauges provide precise measurements. This method is especially valuable in vehicle repair, where assessing the integrity of body panels, ensuring proper fusion during scratch repair or collision repair, and controlling paint thickness are crucial tasks.

The technology’s accuracy and speed make it a preferred choice for professionals in the automotive sector. It enables efficient quality control during manufacturing and streamlines repair processes, reducing the time and cost associated with traditional measurement techniques. With their advanced capabilities, ultrasonic thickness gauges have become an indispensable tool, enhancing precision and productivity in vehicle repair procedures.

Setting Realistic Timeline Expectations for Assessments

Setting realistic timeline expectations is paramount when utilizing an ultrasonic thickness gauge for assessments. These advanced tools provide precise measurements, but their effectiveness depends on various factors. It’s crucial to understand that preparation and the complexity of the material or component being evaluated can significantly influence the assessment time. For instance, in automotive body work or vehicle restoration, where intricate dent removal processes are involved, allowing ample time for each step ensures accurate results without rushing.

Realistic timelines also account for potential adjustments based on gauge calibration and environmental conditions. Proper training of personnel and adherence to manufacturer guidelines ensure consistent and reliable measurements, further optimizing the assessment process. By considering these aspects, users can effectively manage expectations, ensuring efficient workflows in their respective industries, be it automotive or any other field relying on ultrasonic thickness gauges for critical assessments.

Best Practices for Accurate Results and Efficient Workflows

Achieving accurate and reliable results with an ultrasonic thickness gauge requires adherence to best practices. First, ensure proper calibration and maintenance of the device to guarantee its accuracy over time. Regular checks and adjustments according to the manufacturer’s guidelines are essential. Next, for efficient workflows in vehicle repair or car paint services environments, establish clear protocols for sample preparation. This includes cleaning the surface thoroughly and ensuring it’s free from any debris that could interfere with measurements, especially when assessing materials like car dent repairs.

Organized procedures also streamline operations. Assign specific roles and responsibilities to team members, promoting a seamless process from measurement to interpretation. Additionally, training staff on the gauge’s functionality and the significance of each reading can reduce errors and enhance overall efficiency in car dent repair scenarios.

Ultrasonic thickness gauges offer a non-destructive and efficient method for measuring material thickness, making them an indispensable tool in various industries. By understanding the technology and implementing best practices, organizations can ensure accurate and consistent results. When setting timeline expectations for assessments, it’s crucial to consider factors like sample complexity, measurement accuracy requirements, and the number of measurements needed. By following these guidelines, businesses can streamline their processes, enhance productivity, and make informed decisions based on reliable ultrasonic thickness gauge data.