Ultrasonic thickness gauges are advanced, non-destructive tools that use sound waves to accurately measure material depth without damaging surfaces. Portable devices offer compact size, real-time data logging, and connectivity, ideal for on-site measurements in automotive repair, manufacturing, and more. Stationary models are robust, reliable, and suitable for demanding industrial environments like collision repair, ensuring consistent, accurate thickness data crucial for quality control and safety.

In today’s advanced manufacturing landscape, precise material analysis is paramount. Among the array of tools available, ultrasonic thickness gauges stand out for their non-destructive testing capabilities. This article delves into the comparison between portable and stationary ultrasonic thickness gauge devices, exploring their unique advantages and applications. Understanding these technologies empowers manufacturers to make informed decisions, enhancing quality control and efficiency in various industries.

- Understanding Ultrasonic Thickness Gauge Technology

- Portable Devices: Advantages and Applications

- Stationary Gauges: Precision and Industrial Use Cases

Understanding Ultrasonic Thickness Gauge Technology

Ultrasonic thickness gauges are advanced devices that utilise sound waves to measure the depth or thickness of materials non-destructively. This technology has revolutionised industries such as automotive, manufacturing, and even dent repair by providing accurate and efficient measurements. The ultrasonic gauge emits high-frequency sound pulses onto the surface of a material; these pulses travel through until they bounce back, known as echo, which is then measured to determine thickness.

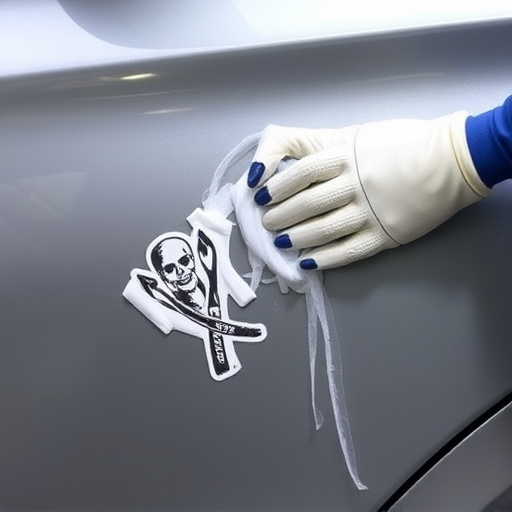

This innovative approach allows for precise assessments without causing any damage to the surface or structure being analysed, making it ideal for quality control in various sectors. Whether it’s ensuring the integrity of car body panels during bumper repair or gauging material thickness in industrial applications, ultrasonic thickness gauges offer a fast, reliable solution. Their versatility and accuracy make them indispensable tools in modern workshops and manufacturing environments.

Portable Devices: Advantages and Applications

Portable ultrasonic thickness gauge devices offer a range of advantages that make them indispensable tools in various industries. Their compact size and lightweight design enable ease of use and transportation, allowing technicians to perform measurements in hard-to-reach areas or on-site at client locations. This is particularly beneficial for businesses providing services such as vehicle paint repair, tire services, and auto body repair, where quick, efficient, and accurate thickness gauge readings are essential.

Moreover, portable devices often incorporate advanced features like real-time data logging and connectivity options, facilitating detailed record-keeping and remote monitoring. Their versatility allows for their application in diverse scenarios, from quality control in manufacturing to inspection of storage tanks and pipelines. This wide range of use cases underscores the importance of portable ultrasonic thickness gauges as versatile tools that enhance efficiency and precision across industries.

Stationary Gauges: Precision and Industrial Use Cases

Stationary ultrasonic thickness gauges are designed for precision measurements in industrial settings. These devices offer a consistent and accurate way to gauge the thickness of various materials, making them indispensable in manufacturing, automotive collision repair, and vehicle dent repair processes. Their robust build quality ensures longevity, even in demanding environments, which is crucial for maintaining high standards in auto body repair.

In industrial applications, the ability to quickly and reliably measure material thickness is vital. Stationary gauges provide precise data, enabling efficient quality control and ensuring compliance with strict industry standards. This precision is especially beneficial in the automotive sector, where even minor variations in metal thickness can impact vehicle performance and safety.

When comparing portable and stationary ultrasonic thickness gauges, each offers unique advantages. Portable devices excel in flexibility and accessibility, making them ideal for on-site measurements and diverse applications. Conversely, stationary gauges prioritize precision and consistency, making them indispensable in industrial settings that demand high accuracy. Ultimately, the choice between these technologies depends on the specific needs of the user, with both options contributing significantly to the field of ultrasonic thickness gauge technology.