The ultrasonic thickness gauge revolutionizes collision repair by offering precise metal thickness measurements, enabling accurate damage assessments and efficient repairs on various car models like Mercedes Benz. Its non-destructive testing capability ensures meticulous care in paint repairs by detecting slight variations in metal thickness, making it a critical innovation for industry quality control.

The future of collision repair is here, and it’s guided by precise technology: the ultrasonic thickness gauge. This innovative tool is revolutionizing the industry with its advanced measurement capabilities, ensuring repairs that match vehicle manufacturing standards. By providing improved accuracy, these gauges streamline processes, enhance efficiency, and guarantee quality assurance. Discover how ultrasonic thickness gauge technology is transforming collision repair, making it faster, more accurate, and more reliable than ever before.

- Revolutionizing Collision Repair: Ultrasonic Thickness Gauge

- Improved Accuracy: The Heart of Advanced Measurement

- Streamlining Processes: Enhancing Efficiency and Quality Assurance

Revolutionizing Collision Repair: Ultrasonic Thickness Gauge

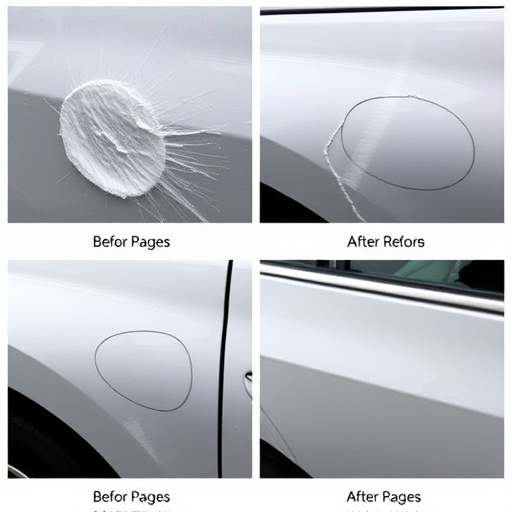

In the ever-evolving landscape of collision repair, technology plays a pivotal role in revolutionizing how we restore vehicles to their pre-accident condition. Among the game changers is the ultrasonic thickness gauge—a sophisticated tool that has transformed the way technicians approach vehicle dent repair and car paint restoration. This innovative device utilizes advanced ultrasonic waves to accurately measure metal thickness, ensuring precise assessments and repairs across various makes and models, including Mercedes Benz repair.

By providing non-destructive testing capabilities, the ultrasonic thickness gauge offers unparalleled accuracy and precision in determining the extent of damage during collision repair processes. Its ability to detect even the subtlest variations in metal thickness facilitates more effective and efficient solutions for car paint repair, ensuring that every vehicle receives the meticulous care it deserves.

Improved Accuracy: The Heart of Advanced Measurement

The future of ultrasonic thickness gauge technology promises unparalleled precision in collision repair. These advanced measurement tools are revolutionizing vehicle repair by providing highly accurate assessments of car bodywork damage. By sending high-frequency sound waves through the material, ultrasonic thickness gauges can detect even the subtlest variations, offering a non-destructive method to measure metal thickness. This level of detail allows technicians to pinpoint exact repair needs, ensuring precise and effective fixes for various types of vehicle damage.

Improved accuracy is at the heart of this advanced measurement technology. Traditional methods may struggle with consistency or require extensive manual intervention, but ultrasonic gauges offer a consistent, automated approach. This not only speeds up the collision repair process but also enhances overall quality control, leading to better outcomes for car bodywork restoration projects.

Streamlining Processes: Enhancing Efficiency and Quality Assurance

In the realm of collision repair, ultrasonic thickness gauges are revolutionizing both efficiency and quality assurance. These advanced tools enable car body shops to streamline their vehicle body repair processes, ensuring precision and speed in automotive body work. By accurately measuring material thickness, ultrasonic thickness gauges help technicians make informed decisions, reducing the risk of human error and enhancing overall repair quality.

In a bustling car body shop environment, this technology plays a pivotal role in optimizing workflow. It allows for real-time data analysis, enabling quick adjustments during the repair process. Consequently, it expedites turnaround times without compromising on the final outcome, making ultrasonic thickness gauges an indispensable asset for any modern collision repair facility.

Ultrasonic thickness gauges are poised to revolutionize collision repair by offering unprecedented accuracy and efficiency. By leveraging advanced measurement technology, these tools enable higher-quality repairs, streamlining workflows and ultimately enhancing customer satisfaction. As ultrasonic thickness gauge technology continues to evolve, it will be fascinating to see its impact on the industry’s future, ensuring precise and timely vehicle restoration.