Ultrasonic thickness gauges are essential non-destructive testing tools for the automotive industry, especially in vehicle body shops and car restoration facilities. They use high-frequency sound waves to accurately measure material thickness without damaging surfaces, ensuring structural integrity, reducing waste, and minimizing rework costs. These gauges are crucial for safety in collision repair and body shop services, providing precise data on metal panels and other components, thereby enhancing overall safety standards. Integrating ultrasonic thickness gauge results into industry standards is vital for shaping the future of car body maintenance and restoration, ensuring work integrity, meeting standards, and optimizing vehicle performance.

“In today’s safety-conscious manufacturing landscape, accurate material thickness measurement is paramount. The ultrasonic thickness gauge emerges as a vital non-destructive testing tool, offering precise and reliable results. This article explores how these advanced gauges support industry standards and best practices by ensuring the integrity of materials used in critical applications. By delving into the principles of ultrasonic technology, we highlight its role in enhancing safety measures and maintaining high-quality production.”

- Understanding Ultrasonic Thickness Gauge: A Non-Destructive Testing Tool

- Ensuring Safety Through Accurate Thickness Measurement

- Integrating Gauge Results into Industry Standards and Best Practices

Understanding Ultrasonic Thickness Gauge: A Non-Destructive Testing Tool

Ultrasonic thickness gauges are non-destructive testing tools that play a pivotal role in ensuring safety standards across various industries, including automotive sectors like vehicle body shops and car restoration facilities. These advanced devices utilise high-frequency sound waves to measure material thickness with remarkable accuracy. By sending an ultrasonic pulse through the material and calculating the time it takes to reflect back, the gauge provides precise thickness data without causing any damage to the surface.

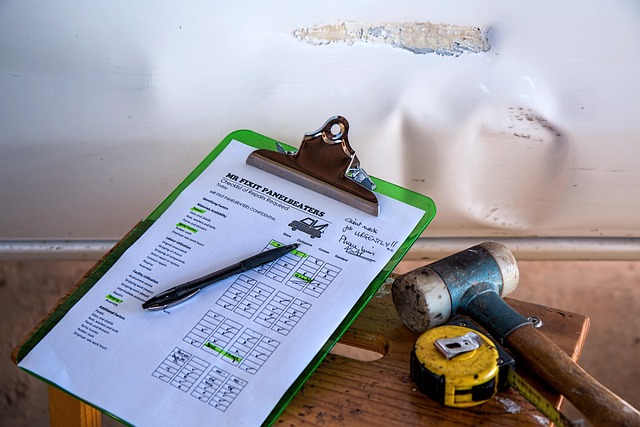

In the context of car bodywork, this technology is invaluable for quality control during manufacturing and repair processes. It helps verify the integrity of panels, ensuring that replacements or repairs meet the required specifications. This non-invasive approach not only maintains the structural integrity of vehicles but also contributes to cost-effectiveness by reducing wastage and the need for extensive rework in car restoration projects.

Ensuring Safety Through Accurate Thickness Measurement

Ensuring safety is paramount in the automotive industry, especially when it comes to vehicle collision repair and body shop services. One crucial aspect that contributes to this goal is accurate thickness measurement using an ultrasonic thickness gauge. This technology plays a vital role in ensuring the integrity of components after repairs, such as metal panels and structural elements. By providing precise data on material thickness, these gauges enable technicians to make informed decisions during collision repair services, thereby enhancing overall safety standards.

An ultrasonic thickness gauge offers consistent and reliable results, which is essential when dealing with varying materials and their potential weaknesses. This precision aids in preventing issues that could compromise the safety of drivers and passengers. In a body shop environment where quality control is paramount, these gauges help maintain high standards, ensuring that each vehicle leaving the facility meets all necessary safety criteria, especially after complex collision repair services.

Integrating Gauge Results into Industry Standards and Best Practices

Integrating gauge results from ultrasonic thickness gauges into industry standards and best practices is a crucial step toward enhancing safety in various sectors, particularly automotive. These advanced measurement tools provide accurate and non-destructive assessments of material thickness, enabling professionals to make informed decisions. For car bodywork services and restoration experts, this technology becomes an indispensable asset. By employing ultrasonic thickness gauges, they can ensure the integrity of their work, especially during complex repairs or modifications.

This integration ensures that standards are met and even surpassed, fostering a culture of quality control in car paint repair and bodywork practices. The data collected from these gauges allows for precise adjustments and optimizations, ultimately leading to enhanced safety features and improved vehicle performance. As industry best practices evolve, ultrasonic thickness gauge results will play a pivotal role in shaping the future of car body maintenance and restoration.

In conclusion, the integration of ultrasonic thickness gauge results has significantly enhanced safety standards across various industries. By providing accurate non-destructive testing solutions, these gauges ensure critical thickness measurements, thereby improving product quality and worker safety. Adopting industry standards and best practices based on such data fosters a culture of reliability and adherence to safety protocols.