Ultrasonic thickness gauges offer a significant advantage in vehicle collision repair, especially for luxury brands like Mercedes Benz, by providing accurate, non-destructive measurements that enhance overall repair quality. They replace slow and error-prone manual methods, saving time and costs through automation. This technology streamlines workflows, improves product quality, enhances productivity, and is crucial for processes like dent removal in bodywork and auto painting. Ultrasonic gauges ensure consistent material properties, critical in intricate repairs like fender restoration, leading to superior quality control and enhanced customer satisfaction.

In manufacturing and material handling, accurate thickness measurement is paramount. Traditional manual tools often fall short, leading to human error and time-consuming processes. This is where Ultrasonic Thickness Gauges shine as innovative solutions. These advanced devices offer unparalleled precision, consistently measuring material thickness with minimal deviation. By automating the thickness assessment process, ultrasonic gauges not only save time but also reduce costs, while ensuring stringent quality control across diverse industries.

- Accurate Measurements: Ultrasonic Thickness Gauge vs Manual Tools

- Time and Cost Savings: Automating Thickness Assessment

- Enhanced Quality Control: Ensuring Consistent Material Properties

Accurate Measurements: Ultrasonic Thickness Gauge vs Manual Tools

In the realm of vehicle collision repair, ensuring precise measurements is paramount for achieving flawless results in Mercedes Benz collision repair or any car body shop. Traditional manual tools, while widely used, can be fallible and time-consuming. Their accuracy often depends on the skill and experience of the technician, leaving room for human error. This is where ultrasonic thickness gauges excel.

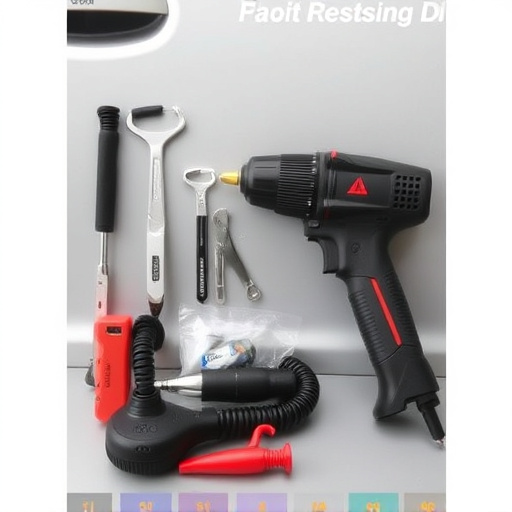

Ultrasonic thickness gauges offer a significant advantage in accurate measurements. These advanced tools utilise high-frequency sound waves to penetrate and measure materials non-destructively. By comparing the time it takes for the wave to travel through the material, these gauges provide precise thickness readings with remarkable consistency. This level of accuracy is crucial when dealing with complex car body repair processes, ensuring that every component is replaced or repaired to the exact required specifications.

Time and Cost Savings: Automating Thickness Assessment

The adoption of ultrasonic thickness gauges brings significant time and cost savings to industries that heavily rely on assessing material thickness, such as automotive manufacturing. Traditional manual methods, involving measurements with calipers or rulers, are not only time-consuming but also prone to human error. With an ultrasonic gauge, the process becomes automated, enabling faster and more accurate thickness determinations. This efficiency is particularly valuable in assembly lines where quick turnaround times are crucial for meeting production deadlines.

Moreover, by eliminating the need for manual labor, companies can reduce operational costs associated with training staff, maintaining tools, and dealing with errors. Automating thickness assessment with ultrasonic gauges is a strategic move that streamlines workflows, improves product quality, and ultimately contributes to enhanced productivity in industries like car bodywork and auto painting, even facilitating smoother dent removal processes.

Enhanced Quality Control: Ensuring Consistent Material Properties

Using an ultrasonic thickness gauge offers a significant advantage in ensuring consistent material properties for various applications, including Mercedes-Benz collision repair and vehicle restoration. Traditional manual tools often rely on subjective human judgment, leading to potential variations in measurements and, consequently, inconsistent results. In contrast, ultrasonic gauges provide accurate, objective data by utilizing sound waves to determine the thickness of materials non-destructively.

This precision is particularly crucial in intricate processes like fender repair, where achieving exact specifications is vital for structural integrity and cosmetic perfection. By employing an ultrasonic thickness gauge, professionals can maintain a consistent standard across all repairs, guaranteeing superior quality control and enhanced customer satisfaction, be it for high-end vehicle restoration or everyday fender repairs.

Ultrasonic thickness gauges offer a significant advantage over manual tools by providing accurate, consistent, and efficient measurements. By automating the thickness assessment process, these innovative devices save time and reduce costs while maintaining enhanced quality control. In today’s competitive market, adopting an ultrasonic thickness gauge can be a game-changer for businesses seeking to streamline their operations and maintain high material property standards.