Ultrasonic thickness gauges provide unparalleled precision and accuracy compared to manual measurement tools, significantly benefiting industries like automotive repair and restoration. These devices use high-frequency sound waves to eliminate human judgment errors, ensuring consistent and standardized measurements. By minimizing human error, ultrasonic thickness gauges enhance quality control, efficiency, and customer satisfaction across multiple sectors, including manufacturing, construction, and medical device production.

In the quest for precise material measurement, ultrasonic thickness gauges offer a revolutionary alternative to traditional manual tools. This article explores the multifaceted benefits of adopting these advanced devices. From enhanced precision and accuracy to increased efficiency and reduced human error, ultrasonic thickness gauges are transforming industries. Their versatility and adaptability make them indispensable in diverse sectors, ensuring consistent, reliable results. Discover how this technology is setting new standards in material handling and quality control.

- Enhanced Precision and Accuracy with Ultrasonic Thickness Gauges

- Increased Efficiency and Reduced Human Error

- Versatility and Adaptability in Various Industries

Enhanced Precision and Accuracy with Ultrasonic Thickness Gauges

Ultrasonic thickness gauges offer a significant advantage over manual tools when it comes to precision and accuracy. Traditional methods often rely on subjective assessments and rough estimates, which can lead to human error and inconsistent results. In contrast, ultrasonic gauges use high-frequency sound waves to measure material thickness with remarkable exactness. This technology ensures that every measurement is taken in a standardized, objective manner, providing consistent data that is crucial for quality control, especially in industries like car repair services and vehicle restoration where precision is paramount.

For instance, in car body restoration, accurate thickness gauge readings are essential to identify damage, determine the extent of repairs needed, and ensure proper panel alignment during the reconstruction process. By employing ultrasonic thickness gauges, restorers can achieve a higher level of detail, resulting in more effective and efficient car repair services. This not only saves time but also enhances the overall quality of the restoration, ensuring that every vehicle returns to the road with a structure as strong and reliable as new.

Increased Efficiency and Reduced Human Error

One of the most significant advantages of ultrasonic thickness gauges over traditional manual tools is the substantial increase in efficiency they offer. Manual measurement techniques often rely on subjective human judgment, leading to inconsistencies and potential errors. In contrast, ultrasonic thickness gauges provide precise and accurate measurements by using high-frequency sound waves to determine material thickness. This technological edge ensures that every assessment is conducted with unparalleled consistency, enabling workers to complete tasks faster and more efficiently.

Moreover, the reduction in human error is a critical benefit of implementing these advanced tools. In automotive repair, auto glass repair, or auto body services, where precision is paramount, minimizing errors can significantly impact overall quality control. Ultrasonic thickness gauges deliver reliable results, ensuring that every component is measured accurately, leading to better-quality repairs and enhanced customer satisfaction.

Versatility and Adaptability in Various Industries

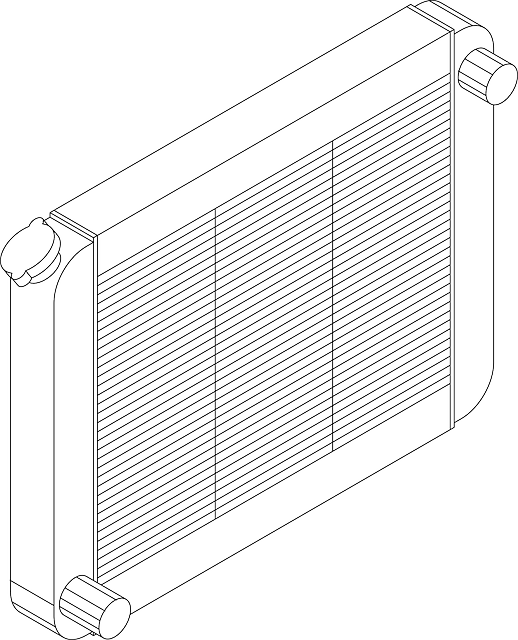

The ultrasonic thickness gauge stands out as a versatile tool with applications spanning numerous industries. Unlike traditional manual methods, this innovative device offers an adaptive solution that caters to diverse needs. In the automotive sector, for instance, it plays a pivotal role in precision fender repair and frame straightening processes, ensuring every adjustment is spot-on. Body shop services benefit greatly from its non-destructive nature, enabling quick and accurate measurements without causing damage to delicate surfaces.

Furthermore, industries like manufacturing, construction, and even medical device production leverage the ultrasonic thickness gauge’s versatility. Its ability to measure various materials, from metal sheets to composite structures, makes it a go-to choice for quality control. This adaptability not only streamlines operations but also enhances overall precision, contributing to better product outcomes across different sectors.

Ultrasonic thickness gauges offer a significant advantage over traditional manual tools, providing enhanced precision and accuracy, increasing efficiency, and reducing human error. Their versatility allows them to adapt to various industries, making them an indispensable asset for modern manufacturing and quality control processes. By adopting ultrasonic thickness gauges, businesses can streamline operations, improve product consistency, and gain a competitive edge in the market.