The ultrasonic thickness gauge transforms auto body repairs with non-destructive sound wave technology to measure metal panel thickness accurately. This tool streamlines damage assessment, quoting, and estimate precision, enhancing efficiency, workmanship standards, and customer satisfaction. Its integration improves repair planning, quote accuracy, pricing competitiveness, and operational streamlining, fostering a reputation for high-quality automotive service. Essential for hail damage repairs and car restoration, ultrasonic thickness gauges aid technicians in effective repair planning and cost-efficient solutions.

“Unleash precision in repair planning and quoting with ultrasonic thickness gauges—a game-changer in the industry. This technology, through its advanced acoustic principles, provides non-destructive measurements, ensuring accurate material thickness assessment. By understanding how these devices work, businesses can capitalize on their advantages. From enhancing quote accuracy to streamlining real-world applications, this article explores why ultrasonic thickness gauges are a must-have tool for efficient and reliable repair processes.”

- Understanding Ultrasonic Thickness Gauge Technology

- Advantages for Repair Planning and Quote Precision

- Real-World Applications and Benefits for Businesses

Understanding Ultrasonic Thickness Gauge Technology

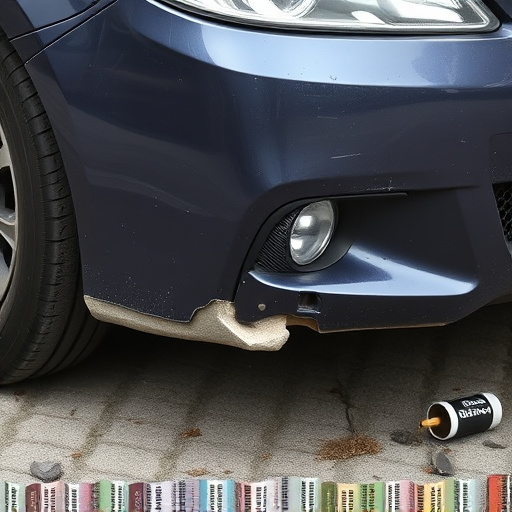

An ultrasonic thickness gauge is a revolutionary tool that has transformed the way auto repair services and car bodywork repairs are executed. This advanced technology uses high-frequency sound waves to measure the thickness of materials, such as metal panels in car bodies. By sending an ultrasonic pulse through the material and calculating the time it takes to bounce back, these gauges provide highly accurate measurements. This non-destructive testing method ensures that auto body repairs are precise and effective without causing any damage to the existing structure.

In the realm of auto repair services, this technology plays a pivotal role in repairing car bodywork by enabling technicians to quickly assess the extent of damage. With an ultrasonic thickness gauge, professionals can accurately determine if panels need replacement or if they can be successfully repaired. This capability not only streamlines the quoting process but also ensures that customers receive fair and accurate estimates for their auto body repairs. By leveraging this innovative tool, auto repair shops can enhance their efficiency, maintain high standards of workmanship, and foster customer satisfaction in every car bodywork repair job.

Advantages for Repair Planning and Quote Precision

The integration of ultrasonic thickness gauges into repair planning and quoting processes offers significant advantages for car body shops, collision centers, and automotive restoration facilities. These advanced tools provide precise measurements of material thickness, enabling more accurate assessments of damage and required repairs. With an ultrasonic thickness gauge, technicians can quickly evaluate the condition of components, such as panels and bodies, ensuring that replacement or repair decisions are based on factual data rather than visual estimates alone.

This precision translates to improved quote accuracy, as the measurements directly influence the scope of work and associated costs. By leveraging the capabilities of ultrasonic thickness gauges, repair facilities can offer more competitive quotes, enhance customer satisfaction, and streamline their operations, ultimately fostering a reputation for high-quality service within the automotive industry.

Real-World Applications and Benefits for Businesses

In the real-world automotive industry, ultrasonic thickness gauges have become indispensable tools for businesses involved in car damage repair and hail damage repair. These non-destructive testing devices play a pivotal role in efficient repair planning and quote generation. By accurately measuring metal thickness, especially after frame straightening procedures, technicians can ascertain the extent of the initial damage. This data is crucial for providing customers with precise, cost-effective solutions.

The benefits extend beyond individual repairs; consistent use of ultrasonic thickness gauges streamlines entire workshops, reducing time wastage and labor costs. Accurate measurements also ensure better resource allocation, minimizing material waste during frame straightening processes. This technology’s contribution to efficient, reliable car damage repair is significant, making it a valuable asset for any business specializing in automotive restoration.

Ultrasonic thickness gauges offer a game-changing approach to repair planning and quote precision. By leveraging advanced technology, these tools provide accurate material measurements, enabling businesses to make informed decisions and deliver more reliable services. In today’s competitive market, adopting an ultrasonic thickness gauge can be a strategic move, fostering efficiency, enhancing customer satisfaction, and ultimately revolutionizing the way repair estimates are generated.