Ultrasonic thickness gauges are essential tools for non-destructive testing in automotive manufacturing and repair, offering precise measurements for various materials and complex geometries. They enable high-quality damage assessment, from car scratch repairs to structural damage, ensuring vehicle safety, integrity, and aesthetic appeal. In Mercedes-Benz shops, these gauges streamline processes like panel replacement and weld inspection, maintaining the brand's quality standards while enhancing productivity.

“Unveiling the versatile world of automotive innovation, this article explores the unique application of ultrasonic thickness gauges, a technology transforming industries. From its basic principles to advanced modern uses, these tools play a pivotal role in ensuring quality and precision.

We’ll delve into the distinct differences between industrial and automotive applications, highlighting how specialized features cater to the unique demands of vehicle manufacturing. Get ready to discover how ultrasonic thickness gauges are revolutionizing the automotive landscape.”

- Understanding Ultrasonic Thickness Gauge Basics

- Industrial vs. Automotive Applications

- Advanced Features in Modern Automotive Models

Understanding Ultrasonic Thickness Gauge Basics

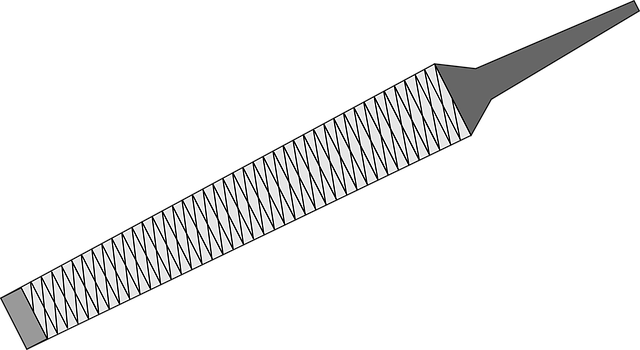

An ultrasonic thickness gauge is a non-destructive testing tool that uses high-frequency sound waves to measure the thickness of materials. It works by emitting an ultrasonic pulse through the material and calculating the time it takes for the echo to return, thereby determining the material’s thickness. This technology is widely used in various industries, including automotive manufacturing and repair. For instance, a Mercedes Benz repair shop might employ these tools to ensure precise panel replacement or body work.

The versatility of ultrasonic thickness gauges makes them invaluable in collision repair shops, where accurate measurements are crucial for restoring vehicles to their pre-accident condition. They are effective in assessing damage, especially in cases of car scratch repair, helping technicians identify the extent of the issue and provide customers with transparent estimates. This simple yet powerful tool plays a significant role in modern automotive care, contributing to efficient repairs and high-quality finishes.

Industrial vs. Automotive Applications

In the realm of automotive applications, ultrasonic thickness gauges play a pivotal role in ensuring precision and quality control during various stages of vehicle manufacturing and repairs. These advanced tools are employed for non-destructive testing (NDT) to measure the thickness of materials used in auto bodies and components, facilitating accurate assessments and decisions in both industrial and luxury vehicle repair settings.

While industrial applications benefit from ultrasonic thickness gauges’ ability to handle diverse material types and complex geometries, automotive repairs, especially in the luxury vehicle sector, demand even greater precision. Auto body repairs often involve intricate designs and high-quality materials, requiring a gauge that can deliver consistent and reliable results. This ensures that every repair, from minor dents to significant structural damage, is addressed with the utmost care, maintaining the integrity and safety of the vehicle without compromising its aesthetic appeal.

Advanced Features in Modern Automotive Models

Modern automotive models boast advanced features that have revolutionized the way vehicles are designed, assembled, and maintained. One such innovation is the integration of ultrasonic thickness gauges in various applications across different car brands. These smart tools play a pivotal role in ensuring precision and quality control during manufacturing processes, particularly in weld inspection and material thickness measurement.

For instance, in the realm of mercedes benz repair, body shop services benefit immensely from ultrasonic thickness gauges for accurate dent removal and precise panel replacement. This technology enables technicians to quickly assess damage, measure underlying panels, and ensure seamless repairs, contributing to the vehicle’s overall structural integrity. Such advanced features not only enhance productivity but also uphold the high standards expected in premium car brands like Mercedes-Benz.

Ultrasonic thickness gauges have evolved significantly, with advanced features tailored for automotive applications, ensuring precision and efficiency in vehicle manufacturing. While industrial uses remain prevalent, the automotive sector leverages these tools to meet stringent quality standards, particularly in modern electric vehicle (EV) models. By understanding the basic principles and exploring the unique demands of the automotive industry, professionals can harness the full potential of ultrasonic thickness gauges to drive innovation and enhance overall vehicle performance.