An ultrasonic thickness gauge uses high-frequency sound waves to measure material thickness non-destructively, offering precise data for industries like automotive and aerospace. Reliability is ensured through regular calibration and testing, crucial for dependable results in vehicle repairs. Interpretations require understanding material characteristics and echo patterns, factoring in surface conditions and gauge calibration for accurate analysis.

Unraveling the secrets of an ultrasonic thickness gauge is crucial for precise material analysis. This advanced technology provides accurate non-destructive measurements, making it a game-changer in various industries. By sending high-frequency sound waves through materials, these gauges determine thickness with remarkable accuracy. In this guide, we’ll walk you through mastering this tool: from understanding the tech behind it, calibrating your gauge, to interpreting measurements for insightful material evaluations using ultrasonic thickness gauge techniques.

- Understanding Ultrasonic Thickness Gauge Technology

- Accurately Calibrate and Test Your Gauge

- Interpreting Measurements for Material Analysis

Understanding Ultrasonic Thickness Gauge Technology

An ultrasonic thickness gauge is a sophisticated tool used to measure the thickness of materials non-destructively. It utilizes high-frequency sound waves, typically in the ultrasonic range (above 20 kHz), which are transmitted through the material being measured. The time it takes for the wave to travel from the sensor to the other side and back is precisely measured, allowing the gauge to calculate the thickness based on the speed of sound in that specific material. This technology is especially valuable in industries where precision thickness measurement is crucial, such as automotive, aerospace, and manufacturing.

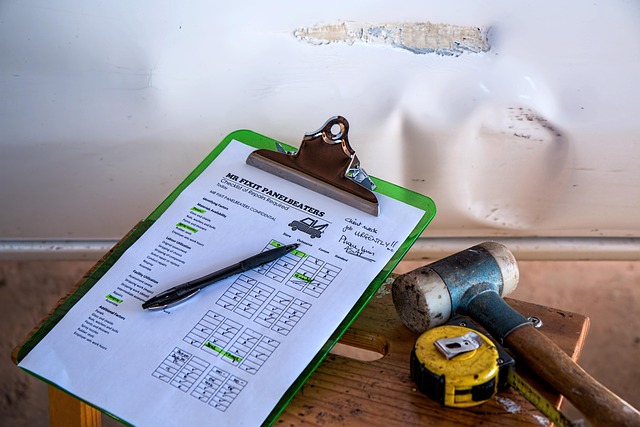

In applications like luxury vehicle repair, for instance, an ultrasonic thickness gauge can be instrumental in assessing panel damage, including subtle dents or impacts, which might not be apparent through visual inspection. Similarly, in the realm of car dent repair, this tool enables technicians to accurately determine the depth of a scratch repair, ensuring that the material is restored to its original specifications without over-or under-filling. This level of precision contributes to the overall quality and longevity of repairs, whether it’s for a luxury vehicle or a regular family car.

Accurately Calibrate and Test Your Gauge

Before relying on your ultrasonic thickness gauge for critical measurements, ensure it’s accurately calibrated and tested. Calibration ensures the device provides precise readings, which is paramount in industries like automotive repair, particularly in car collision repair or car bodywork services. Start by following the manufacturer’s guidelines for calibration procedures, which often involve comparing known standards to adjust the gauge’s sensitivity. Regular testing against these standards helps maintain accuracy over time.

Consider setting up a routine maintenance schedule where you periodically recalibrate and test your gauge. This meticulous approach guarantees that, when measuring materials like metal panels or plastic components in collision centers, your ultrasonic thickness gauge yields dependable results. Inaccurate readings can lead to incorrect assessments and substandard car bodywork services, so this step is non-negotiable for achieving precision.

Interpreting Measurements for Material Analysis

When interpreting measurements from an ultrasonic thickness gauge, understanding material characteristics becomes crucial. This non-destructive testing method emits high-frequency sound waves into a material to measure its thickness. The key lies in deciphering the echoes returned. For instance, in an auto maintenance or vehicle collision repair scenario, comparing measured thicknesses with known specifications can reveal damage extent. A discrepancy might indicate delaminations, hidden cracks, or areas of previous repairs, guiding targeted inspections and informed decisions.

The precision of ultrasonic thickness gauge readings is contingent on various factors, including material properties, surface conditions, and gauge calibration. Professionals in car repair shops must account for these variables to ensure accurate analysis. Regular calibration and adherence to manufacturer guidelines are essential practices to maintain the integrity of measurements, ensuring effective evaluation of components during vehicle collision repairs or regular auto maintenance routines.

An ultrasonic thickness gauge is a versatile tool that enables precise material analysis by accurately measuring thickness. By understanding the technology, calibrating correctly, and interpreting measurements, you can gain valuable insights into the properties of various materials. This knowledge ensures reliable results, making it an indispensable resource for industries reliant on accurate thickness determination.